- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

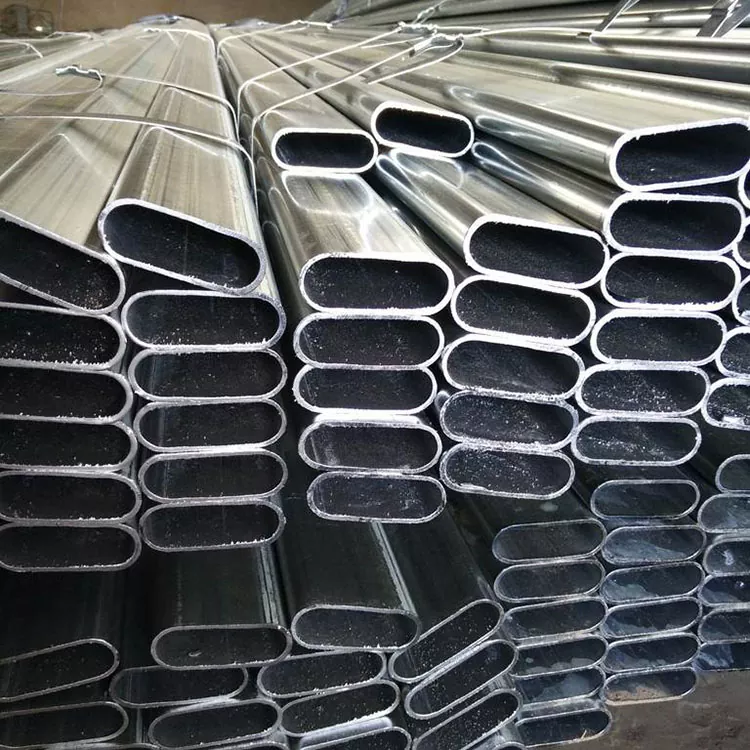

Thin-Walled Straight Seam Welded Pipe

Send Inquiry

It is characterized by light weight, high strength and relatively low production cost.The manufacturing materials of Xinlida’s China Thin-Walled Straight Seam Welded Pipe is mostly low carbon steel or stainless steel, and different materials are selected according to application requirements.This kind of pipe has good plasticity and weldability, and is easy to process into various shapes.Thin-Walled Straight Seam Welded Pipe is more convenient in transportation and installation, because their lighter weight can reduce the burden on the support structure.The surface of thin-walled welded pipe can be galvanized, sprayed and other treatments to enhance its corrosion resistance.

The manufacturing process of thin-walled welded pipe mainly includes the following steps: selecting proper metal strip as raw material, and determining the material and thickness of the strip according to the requirements of the final product.The strip is coiled into a tube by a forming machine, and the coiling precision needs to be controlled in the forming process so as to ensure that the roundness and the size of the tube meet the standard.Next, the welding process is carried out. The commonly used welding methods include high frequency welding, electric arc welding, etc., and the firmness and uniformity of the weld seam shall be ensured during welding.After welding, the pipe is cooled and sized to stabilize its shape and size.Cutting, straightening and surface treatment of tubes, such as deburring, polishing or plating, to improve appearance and performance.Process parameters shall be strictly controlled throughout the manufacturing process to ensure product quality.Thin-walled welded pipe is used widely in many industries.In the construction field, it is often used in indoor piping system, support structure and decorative components, because of its lightweight and easy to install the characteristics of the favored.In furniture manufacturing, thin-walled welded pipes can be used to make table and chair frames, storage shelves, etc., providing stable support while reducing overall weight.In the automotive industry, thin-walled welded pipes are used in exhaust systems, chassis parts, etc., with high strength and corrosion resistance to meet the needs of vehicle operation.Thin-walled welded pipes are also used in agricultural irrigation systems, HVAC piping, and in the framing of some machinery and equipment.These applications reflect the diversity and practicality of thin-walled welded pipe.