- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

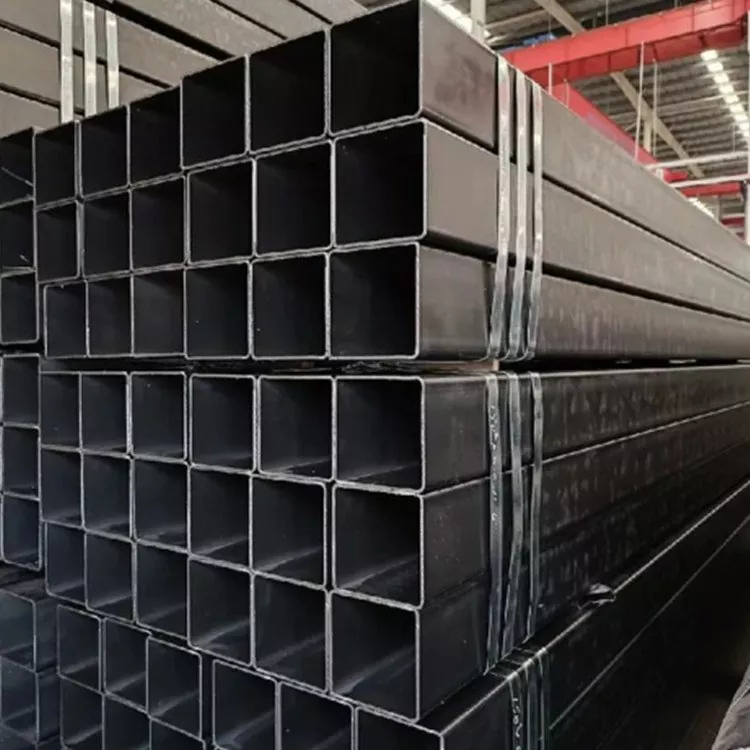

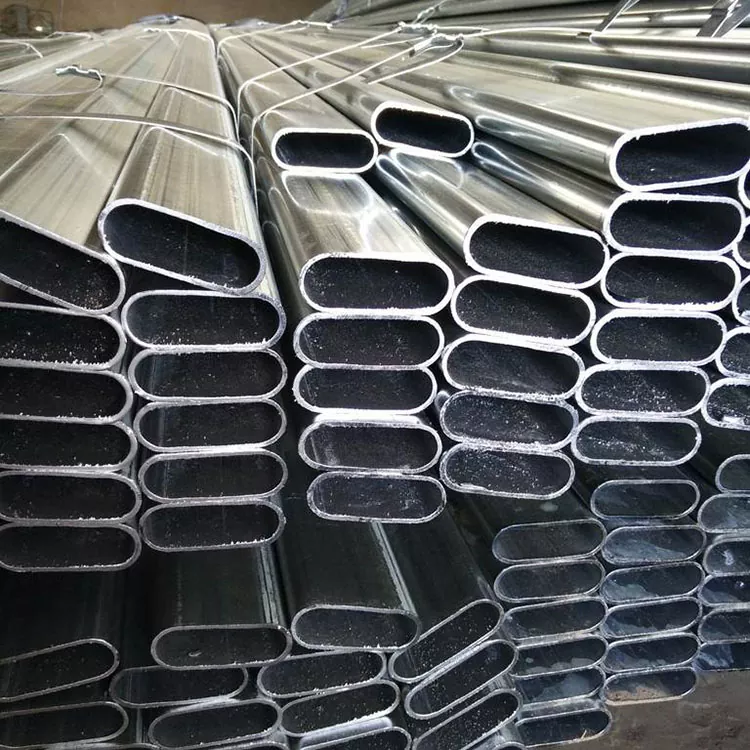

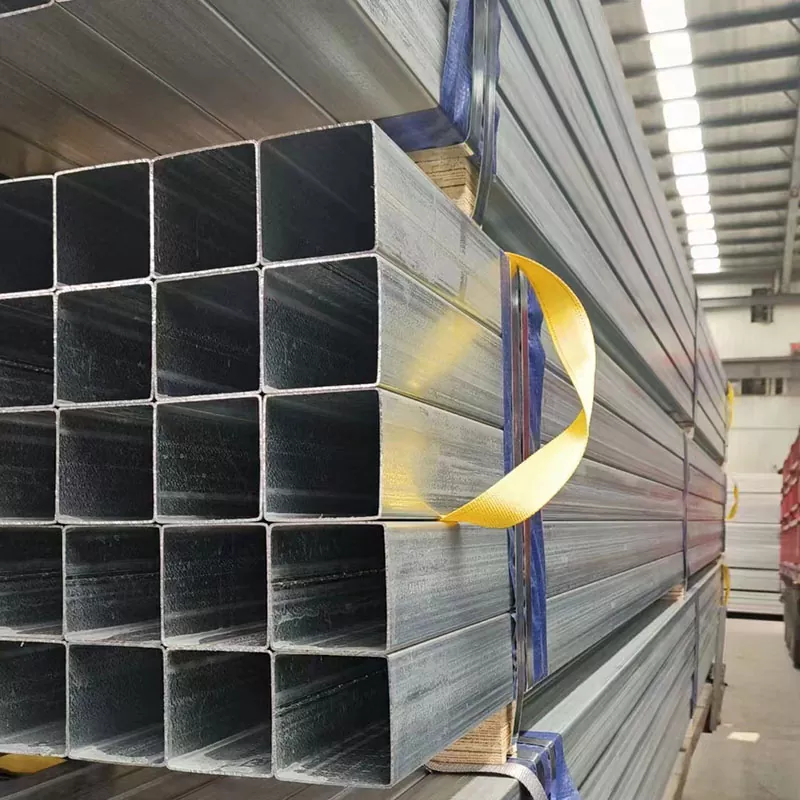

Black Striped Rectangular Tube

Send Inquiry

The cornerstone of Xinlida’s China Black Striped Rectangular Tube quality lies in raw materials.We are aware of this, so we have established strict screening standards in the raw material procurement process to ensure that each batch of raw materials meets high quality requirements.In the production process, each steel pipe must undergo strict chemical composition analysis and mechanical properties test before leaving the factory, and the content of harmful elements such as sulfur and phosphorus will be controlled at a very low level, laying a solid foundation for the strength, toughness and workability of the product.

The product adopts multi-pass cold roll forming technology to ensure that the steel strip is smoothly and accurately deformed into the required rectangular section.In the high-frequency welding process, we strictly control the welding temperature, speed and pressure, and strive to achieve full fusion of the weld, so that the weld strength is close to the base metal, while ensuring that the weld surface is smooth and smooth.After welding, the pipe will also undergo sizing and straightening procedures to eliminate internal stress, correct tube bending and torsion, and ensure that the straightness, verticality and right angle accuracy of the black square tube meet the application standards.

Our common implementation standards for black belt square tubes include GB/T 3091-2015 "Welded steel tubes for low pressure fluid transmission" and ASTM A500 "Galvanized and painted carbon steel formed tubes for structural use".The product specifications are diverse, with cross-section size ranging from 10 mm to 600 mm to 600mm, wall thickness of 0.5-25 mm, and length of 6 meters. It can also be customized according to customer needs.

If you have steel pipe needs, welcome to contact Tianjin Xinlida Steel Pipe Co., Ltd., we will provide you with suitable steel pipe products.