- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

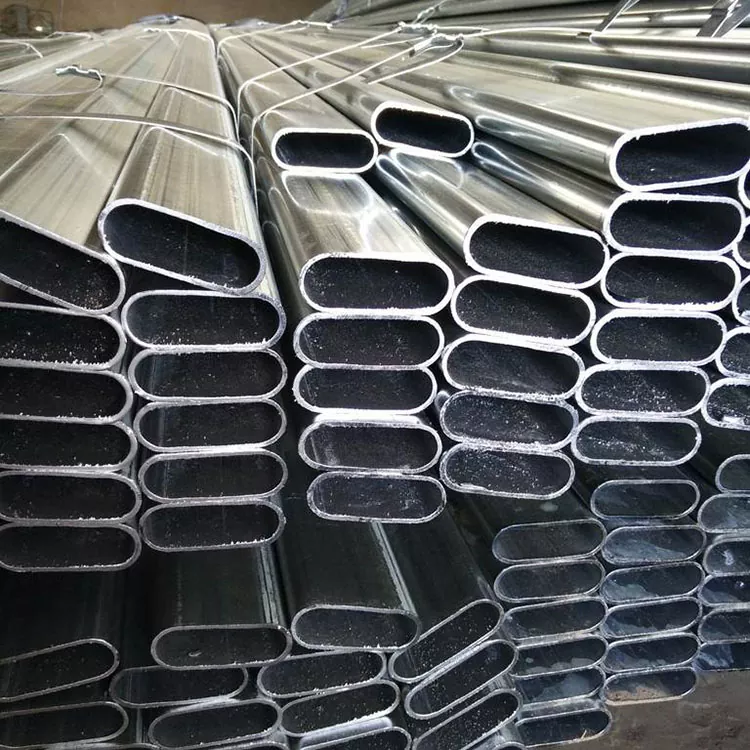

Thin-Walled Rectangular Tube

Send Inquiry

From the point of view of production technology, China Thin-Walled Rectangular Tube mainly has two ways: high frequency welding and cold rolling forming welding.High-frequency welding makes the edge of tube blank rapidly heat up to melt by means of skin effect and proximity effect of high-frequency current, and completes welding under the action of extrusion roller, with high production efficiency and good weld quality; after cold rolling forming, welding is to roll steel strip into required shape and then weld, which can realize more accurate size and better surface quality, but the process is complicated and the cost is slightly higher.

In terms of performance characteristics,"thin wall" is its biggest highlight.Under the premise of ensuring certain strength and rigidity, it greatly reduces its own weight, effectively reduces the cost of materials and transportation, and is convenient for installation and handling.At the same time, it has good plasticity, easy bending, stamping and other processing, and can meet the design requirements of complex shapes.After surface treatment such as zinc plating and painting, it also has good corrosion resistance and can be used in a variety of environments for a long time.

and that application field is also very wide.In the building decoration industry, it is a common material for making light steel structure, indoor partition and door and window frame, adding beauty and modernity to the building; In the field of automobile manufacturing, it can be used for manufacturing body frame and chassis parts to help the lightweight of automobiles and improve fuel economy; In the household appliance industry, it is the ideal choice for the shell and internal bracket of household appliances such as refrigerator and air conditioner, improving the overall performance and stability of products.