- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

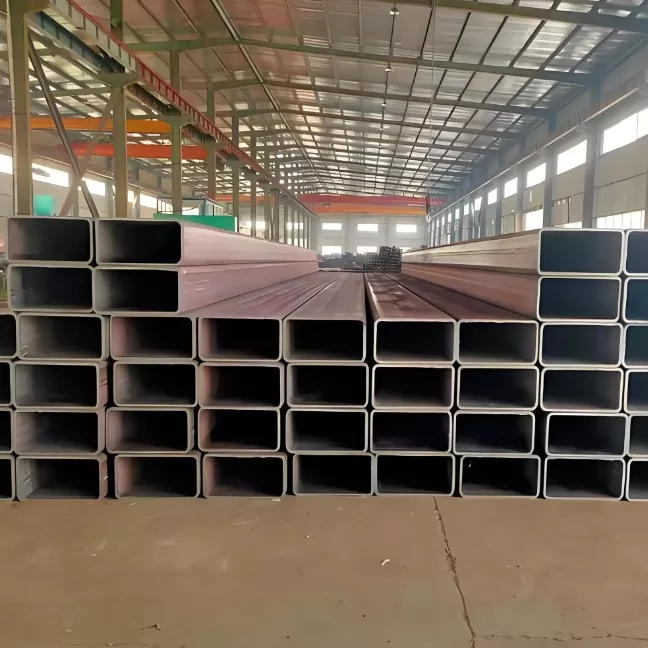

Thick-Walled Rectangular Tube

Send Inquiry

Xinlida’s China Thick-Walled Rectangular Tube, high frequency welding uses skin and proximity effect of high frequency current to instantly heat the edge of tube blank to melt, and quickly weld under the action of extrusion roller, with high production efficiency and good weld quality, suitable for mass production.Cold rolling forming after welding is to roll the steel strip into the required shape by cold rolling and then weld, which can accurately control the size and has better surface quality, but the process is complicated and the cost is slightly higher, which is often used in scenes with high precision requirements.

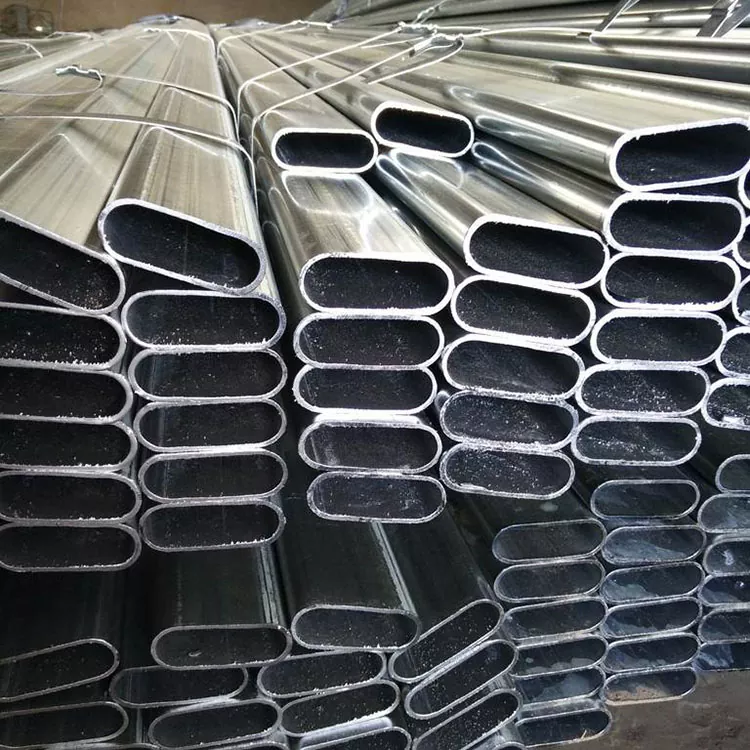

"Thin wall" is its main characteristic.On the basis of ensuring a certain strength and rigidity, the thin-walled square tube greatly reduces its own weight, reduces the material and transportation cost, and is convenient for installation and handling.It has good plasticity, easy bending, stamping and other processing, can meet the design requirements of various complex shapes, and provides the possibility for diversified product design.After surface treatment such as zinc plating and painting, it also has good corrosion resistance and can be used for a long time in a variety of harsh environmental conditions, extending its service life.

In the architectural decoration industry, thin-walled square tubes are often used to make light steel structures, indoor partitions, door and window frames, etc., adding beauty and modernity to buildings; in the automotive manufacturing field, they can be used for the manufacture of body frames and chassis parts to help reduce vehicle weight and improve fuel economy; in the home appliance industry, they are ideal materials for refrigerators, air conditioners and other home appliance shells and internal brackets to improve the overall performance and stability of products.In addition, it can also be seen in the fields of machinery, petroleum, chemical industry, electricity, transportation, etc.