- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

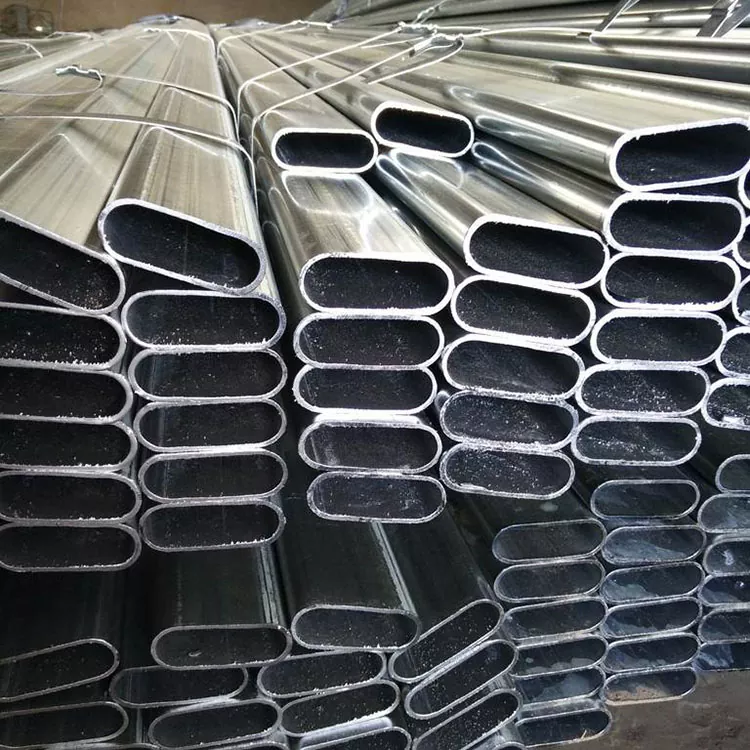

Thick Wall Straight Seam Welded Pipe

Send Inquiry

The main characteristics of Thick Wall Straight Seam Welded Pipe by Xinlida factory include high strength, good pressure resistance, high size accuracy and wide application range.Due to its large wall thickness, this pipe is stable under heavy load or high pressure environment and is not easy to deform or damage.The production process of thick wall straight seam welded pipe mainly includes the following steps: selecting suitable steel plate or strip as raw material, pre-treating, including cleaning surface and cutting to the required size.Next, the steel plate or strip is bent into a tube by a forming device, ensuring that the edges are aligned.The edges are then welded together using a straight seam welding technique such as high frequency welding or submerged arc welding.After welding is completed, necessary follow-up treatments are performed, such as weld dressing, heat treatment to relieve stress, and nondestructive testing to ensure weld quality.Pipe is subjected to size inspection and surface treatment, such as corrosion protection coating or painting, to extend service life.When purchasing thick wall straight seam welded pipe, many factors need to be considered.The material, wall thickness and size of the pipe shall be determined according to the specific application scenario to ensure that it meets the engineering requirements.Check the quality certificate and test report of the pipe to confirm the welding quality and nondestructive testing results.Knowing the process level and reputation of the manufacturer is helpful to select reliable products.In terms of price, the cost of thick wall welded pipe of different specifications may vary, so it is recommended to compare the quotations of multiple suppliers, but do not use price as the basis for decision-making.Tianjin Xinlida steel pipe, professional manufacturer, trustworthy!

When storing thick wall straight seam welded pipe, care should be taken to avoid wet or corrosive environment to prevent rust.Tubes should be laid flat or stacked on flat ground to avoid bending or deformation.Use a cover to protect surfaces from dust or chemicals.During handling, use appropriate tools to avoid damage caused by collision or drop.