- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

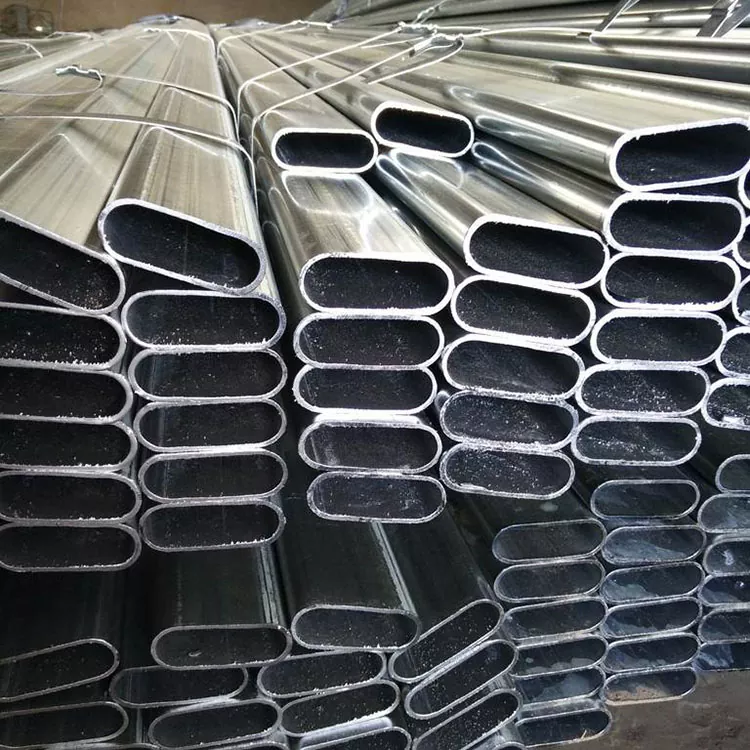

Thick Black Rectangular Tube

Send Inquiry

The Xinlida’s China Thick Black Rectangular Tube producted has the characteristics of uniform welding seam, which ensures that the pipe connection part is smooth and firm, thus significantly improving the strength of the overall structure.In addition, high-frequency welding technology also achieves high production efficiency, helping to shorten production cycles and reduce manufacturing costs.The quality of products produced in this way is stable and reliable, fully in line with relevant national standards and strict requirements in the industry.This process not only ensures the consistency of product performance, but also meets the needs of diverse application scenarios.

Specifications span from 10mm×10mm micro tubes to 600mm×600mm giant tubes, wall thickness covers 0.5-25 mm, length is generally 6 meters, can also be customized according to requirements.This flexibility makes it easy to adapt to different scenarios.In the field of construction, it serves as the core component of scaffold, with a single bearing capacity of up to 5 tons, providing a safety barrier for aerial work; in mechanical manufacturing, its high ductility improves the impact resistance of equipment frame by 40% and prolongs service life; in automobile industry, 0.5mm ultra-thin wall pipe reduces the weight of vehicle body by 15% while maintaining structural strength, helping to improve the endurance of new energy vehicles.

Xinlida's quality control runs through the whole production process.From the beginning of raw material selection, the company strictly follows the standards, never uses recycled scrap steel, and ensures the purity of each square tube.Common implementation standards include GB/T 3091-2015 "Welded steel pipes for low pressure fluid transmission", **ASTM A500 "Galvanized and painted carbon steel formed steel pipes for structure"** and so on.High frequency welding process through electromagnetic induction heating, forming a uniform dense fusion zone, strength than traditional welding increased by 20%.During the production process, each batch of products needs to pass multiple quality inspections to ensure that each product delivered to you meets the requirements.