- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

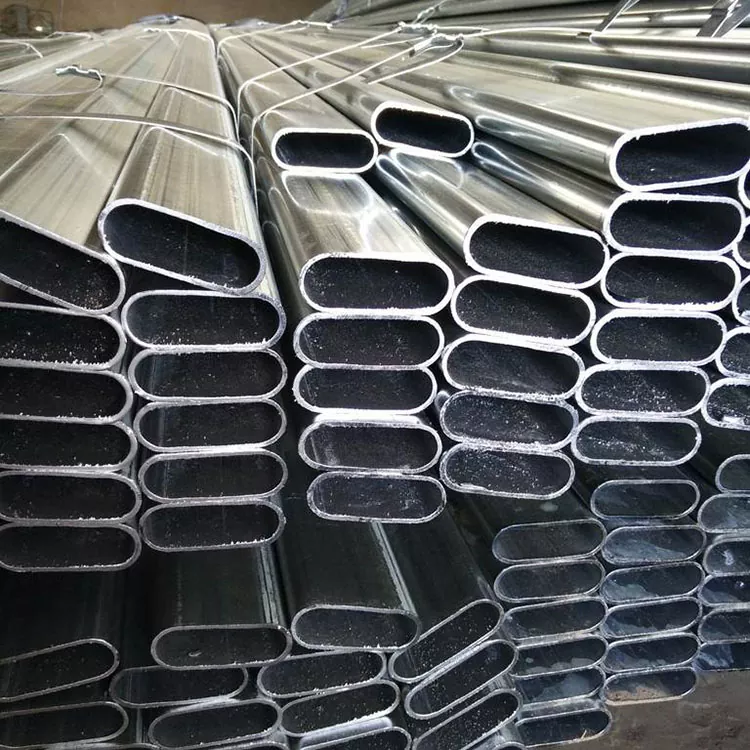

Straight Slit Black Circular Tube

Send Inquiry

The China Straight Slit Black Circular Tube produced by Xinlida factory adopts advanced high-frequency welding technology.This process makes the weld uniform and beautiful, the strength far exceeds the ordinary welding method, and greatly improves the overall performance of the pipe.At the same time, high frequency welding also has the advantages of high production efficiency and low cost, which can achieve large-scale and efficient production on the premise of ensuring product quality and meet the large demand of the market.Product quality is stable and reliable, fully in line with national standards and industry requirements, so that customers can use without worry.

In terms of product specifications and materials, Tianjin Xinlida Steel Pipe Co., Ltd. has demonstrated strong customization capabilities.Product specifications range from DN15 - DN250mm outside diameter, wall thickness 0.5 - 20mm, can also be customized according to customer's special needs size.Commonly used materials include Q235B, Q345B, 16Mn, etc., which can meet the diversified requirements for pipe strength in different scenarios.In addition, the company also provides a variety of surface treatment methods, such as hot dip galvanizing, plastic coating, anti-corrosion coating, etc., effectively improve the corrosion resistance of pipes and prolong their service life.

In terms of production technology and quality control, the company also strives for excellence.High-frequency welding technology is adopted, and on-line heat treatment equipment is equipped to further improve weld toughness.Before leaving the factory, each pipe shall undergo strict inspection in the whole process such as hydrostatic test, ultrasonic flaw detection, size accuracy detection, etc., and strictly implement GB/T 3091 - 2015, ASTM A53 and other domestic and foreign standards to ensure product quality.