- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

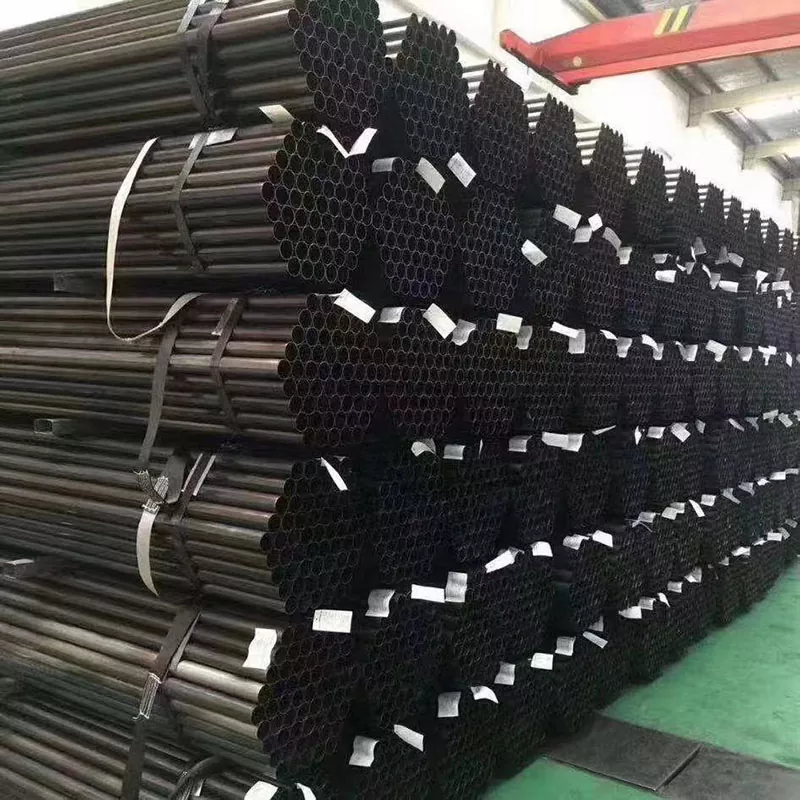

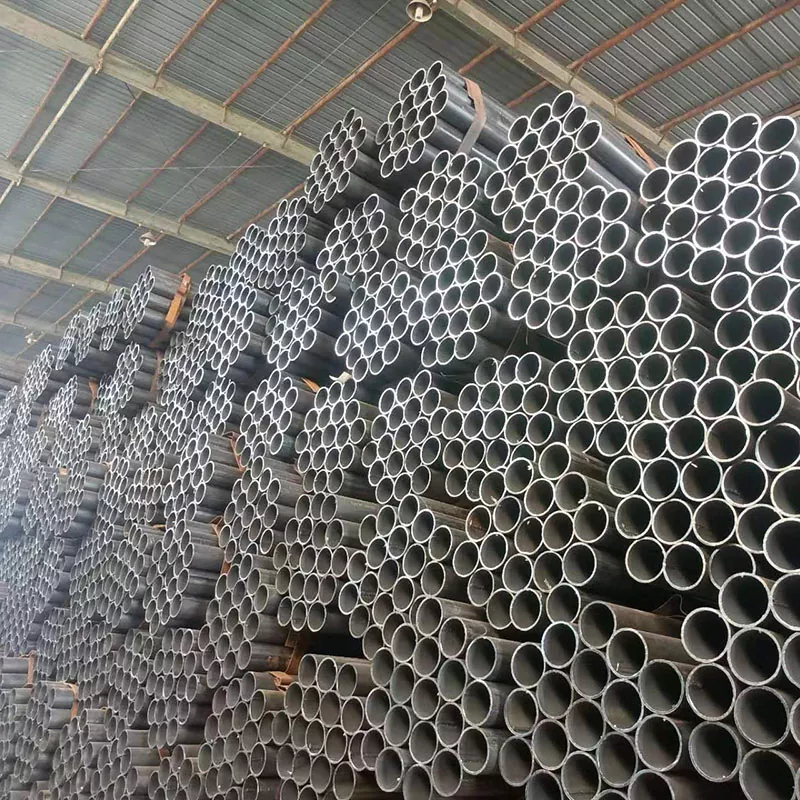

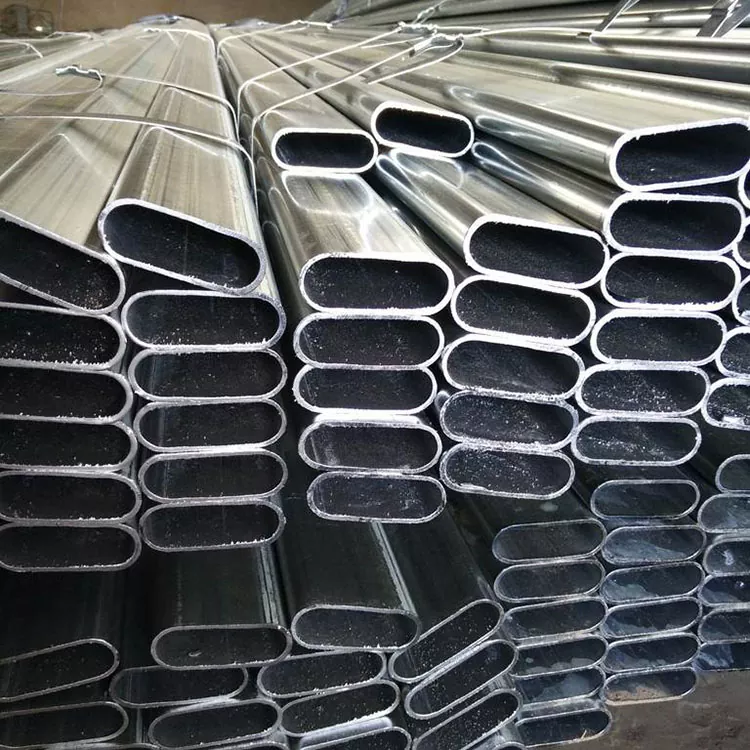

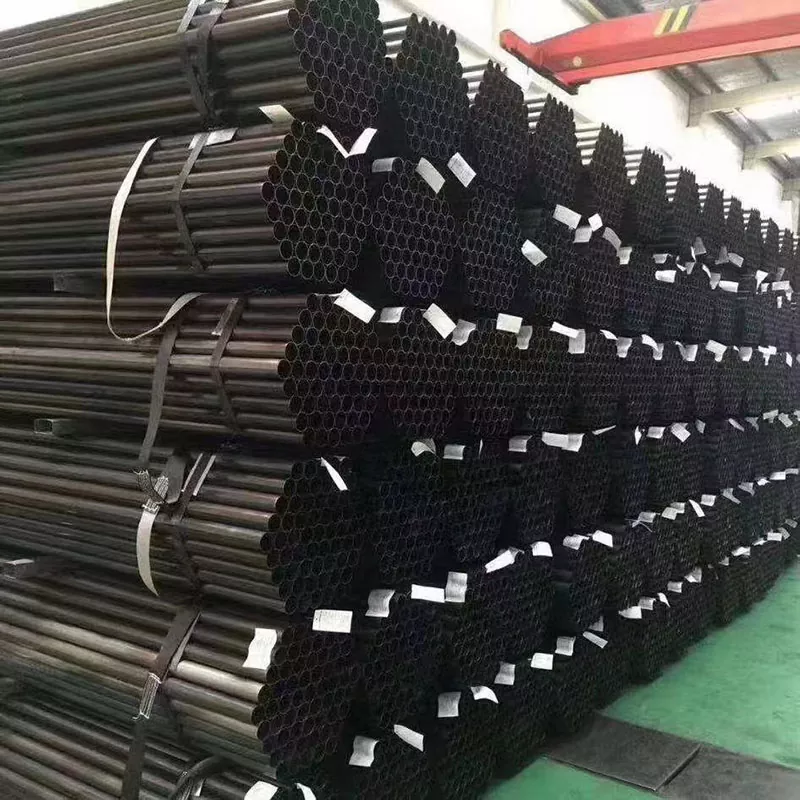

Longitudinal Welded Pipe

Send Inquiry

The manufacturing process of Longitudinal Welded Pipe follows the core process of "raw material pretreatment-forming-welding-finishing", and each step revolves around precision and strength control.The method comprises the following steps of: firstly, preparing raw materials, selecting a hot-rolled steel strip or a coil plate as a base material, cutting the steel strip into a width conforming to pipe diameter requirements through a slitting machine, and then performing leveling and derusting treatment to remove surface oxide scales and impurities so as to avoid affecting welding quality; and then entering a forming stage, wherein the steel strip is gradually bent into an open round tube blank (or square or rectangular tube blank) through a continuous roller forming machine, so as to ensure that the edges of the tube blank are aligned and the curvature is uniform, and lay a foundation for subsequent welding.

After forming, the tube blank immediately enters the welding link, and the mainstream adopts high-frequency induction welding or arc welding: high-frequency welding uses electromagnetic induction to rapidly heat the edge of the tube blank to a molten state, and then the welding is completed by pressing the extrusion roller, and the weld strength is close to the base metal; arc welding is suitable for thick-walled tubes, and the connection is realized by filling the molten pool with an electrode or a welding wire.After welding, weld inspection (such as ultrasonic and X-ray inspection) shall be carried out to eliminate defects such as pores and cracks, calibrate pipe diameter by sizing machine, correct straightness by straightening machine, and finally cut into fixed length, and carry out end surface processing and anti-corrosion treatment (such as galvanizing and painting) to finally form qualified straight welded pipe products.