- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

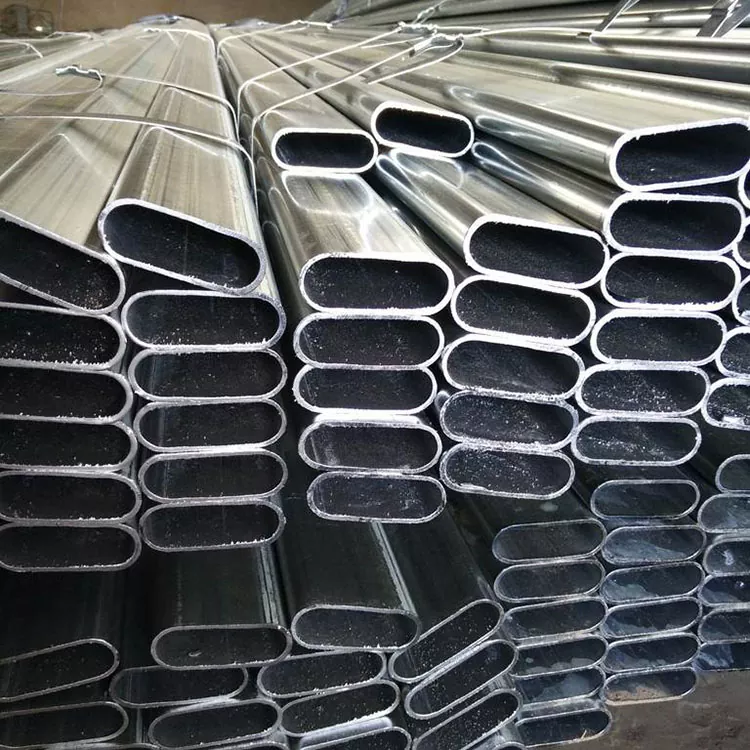

Large Diameter Galvanized Pipe

Send Inquiry

From common building structure construction, such as frame support of large factory buildings, dome structure of sports stadiums, bridge construction in municipal engineering, laying of urban underground pipe gallery, oil and gas transmission pipeline in energy field, water diversion channel of water conservancy project, etc., large-diameter characteristics make it easy to cope with various large-scale and high-load use scenarios, providing solid guarantee for the stability and safety of the project.

Galvanizing is a key advantage for large diameter tubes.A uniform and compact zinc layer is formed on the surface of the pipe by hot dip galvanizing or zinc plating.This layer of zinc is like a layer of strong protective clothing, which can effectively isolate air, moisture and corrosive media from contact with the pipe matrix, greatly slowing down the corrosion rate of the pipe.Even in humid, acid-base and other harsh environments, it can maintain a long service life, reducing the cost of frequent pipe replacement and maintenance workload.

The large diameter design allows galvanized tubes to have a large moment of inertia, resulting in excellent structural stability and load carrying capacity.When it bears large pressure, tension or bending moment, it can keep its shape unchanged and is not easy to deform or damage.This allows it to perform well in heavily loaded building structures and piping systems carrying high pressure fluids, ensuring safe operation of the project.

Xinlida’s China Large Diameter Galvanized Pipe are usually produced in a standardized way, with high size accuracy and various interface forms, such as threaded connection, flange connection, welding, etc., which are convenient for on-site installation and disassembly.Moreover, its weight is relatively light (compared with other materials with the same bearing capacity), and it is convenient to carry and hoist, which can greatly shorten the construction cycle, improve the construction efficiency and reduce the construction cost.

Galvanized tubes have little impact on the environment during production and use.Zinc is a recyclable metal, and the zinc coating can be reused by recycling at the end of its service life, reducing resource waste.At the same time, its good corrosion resistance also reduces the risk of leakage caused by pipe corrosion, which is of great significance for protecting soil and water environment.