- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

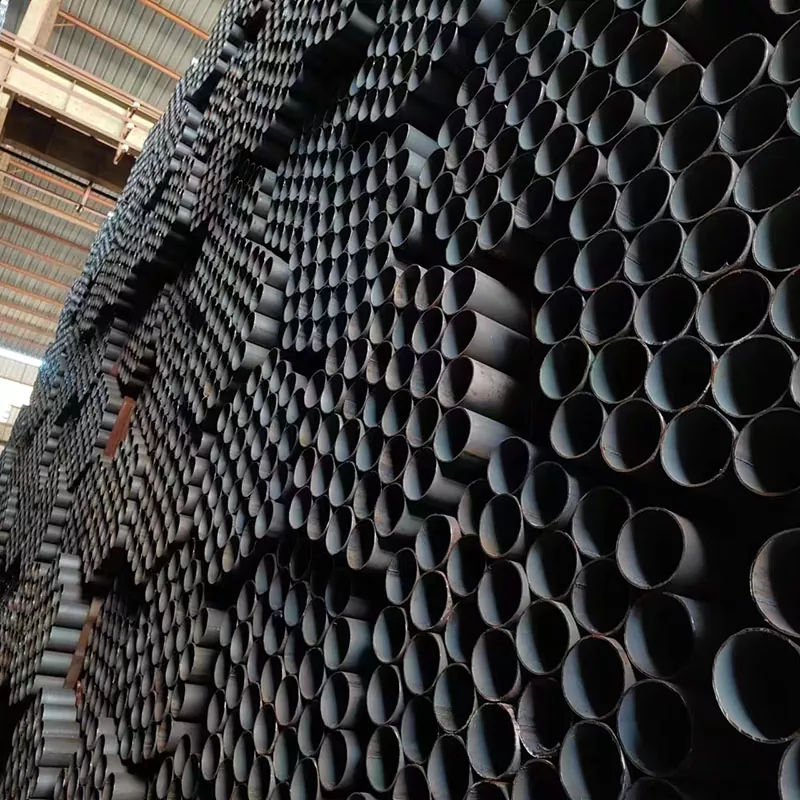

Black Circular Tube

Send Inquiry

In terms of Xinlida China Black Circular Tube’s materials, Q235B, Q345B, 16Mn, etc. are commonly used. These materials have different strength characteristics and can meet the requirements of different engineering on pipe strength.For example, in the field of oil and gas transportation under high pressure, high-strength materials can ensure safe and stable operation of pipes.

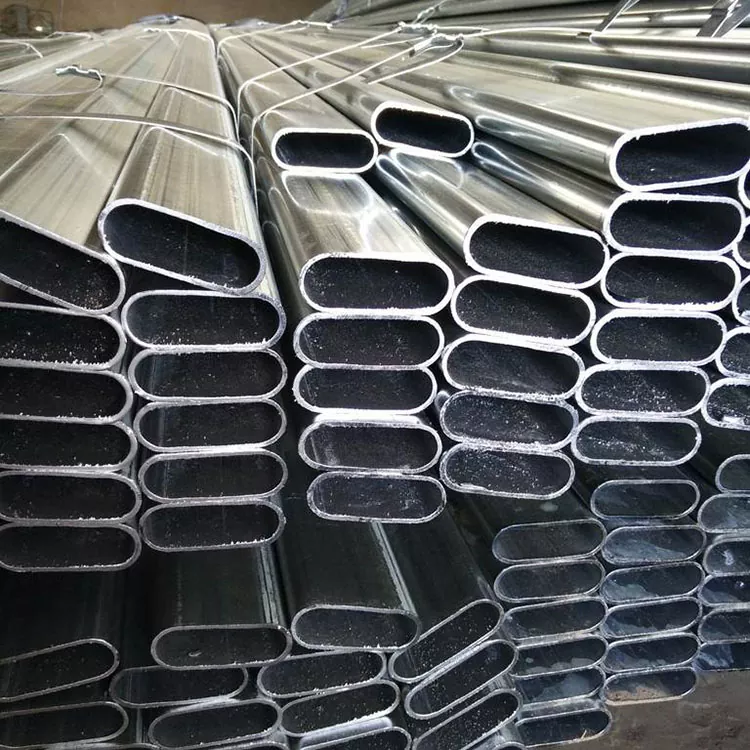

In order to improve the corrosion resistance of black round tubes, Tianjin Xinlida provides a variety of surface treatment methods.Hot-dip galvanizing treatment can form a dense zinc layer on the surface of the pipe, effectively isolating air and moisture to prevent rust of the pipe; plastic coating treatment is to coat a layer of plastic on the surface of the pipe, which not only resists corrosion, but also has good wear resistance and insulation; anti-corrosion coating treatment can be selected according to different use environments to further extend the service life of the pipe.

Tianjin Xinlida Steel Pipe Co., Ltd. adopts high frequency welding technology to make the black pipe weld uniform, high strength and meet the national standards.At the same time, equipped with online heat treatment equipment, improve weld toughness, enhance the overall performance of the pipe.In the quality inspection link, the pipe shall undergo the whole process inspection such as hydrostatic test, ultrasonic inspection, size accuracy inspection, etc. before leaving the factory, and strictly implement GB/T 3091 - 2015, ASTM A53 and other domestic and foreign standards to ensure that each black round pipe is of excellent quality.