- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

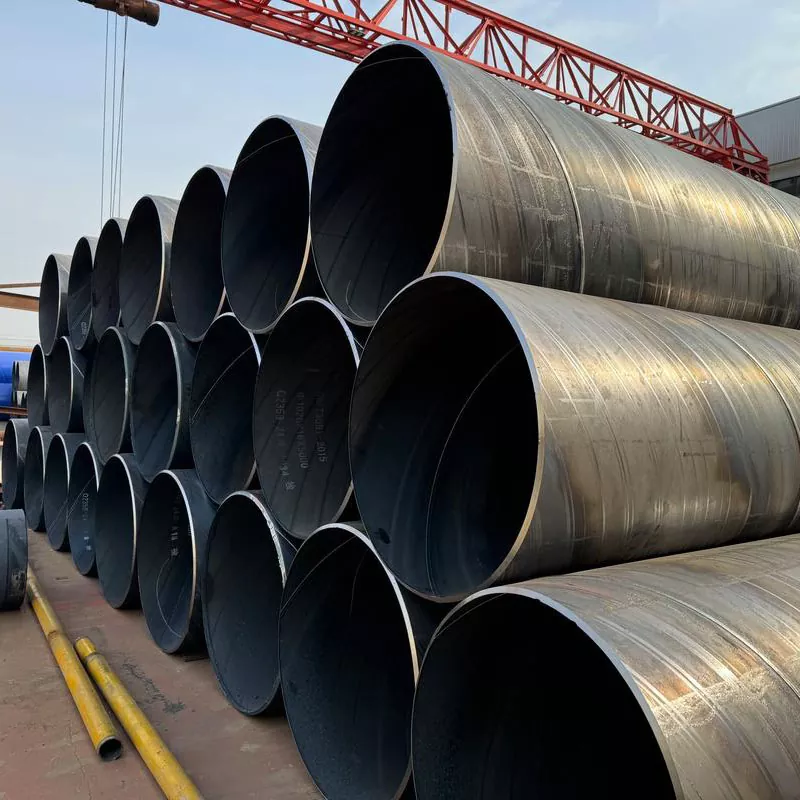

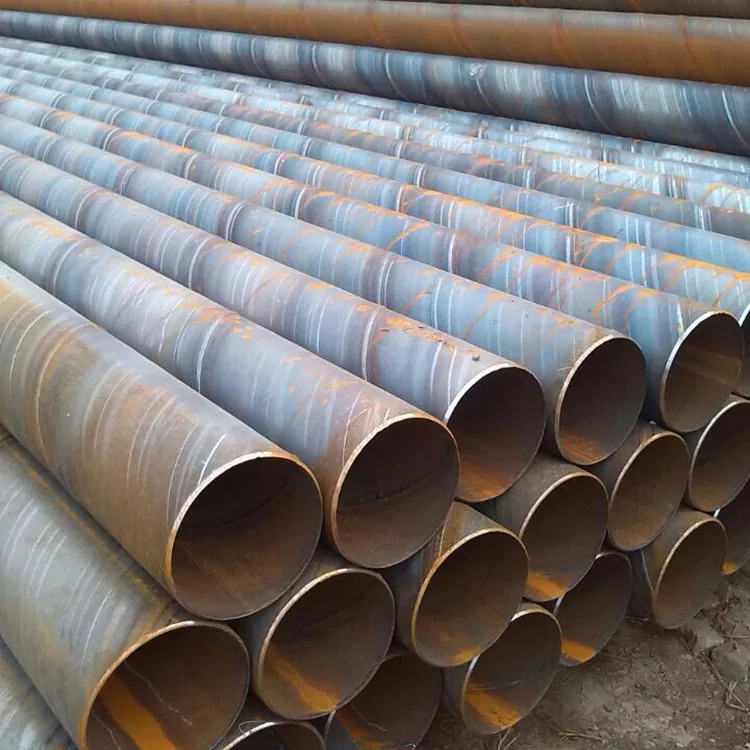

Black Spiral Welded Pipe

Send Inquiry

China Black Spiral Welded Pipe produced by Xinlida adopts double-sided submerged arc welding technology and wound submerged arc welding technology, and the weld is uniform and spiral distributed.This unique process gives steel pipes many advantages.Its strength is higher than that of straight seam welded pipe, spiral weld makes steel pipe withstand internal pressure stronger, especially suitable for high pressure scenes such as water supply and drainage, gas, steam, petrochemical and other liquid gas transmission, but also for building scaffolding, bridge structure, dock, road guardrail and other structural support to provide stable protection, but also can be applied to automobile transmission shaft, hydraulic support, engineering machinery structural parts and other mechanical manufacturing fields.

The company can produce pipes with an outer diameter of 10 - 1200mm and a wall thickness of 1.5 - 20mm to meet the diverse needs of different customers.High production efficiency, so that the daily output can reach hundreds of tons, suitable for large-scale industrial production.Compared with seamless steel pipe, its production process is short, energy consumption is low, and the price is more competitive.

After uncoiling, leveling and spiral forming, the raw material steel strip is welded by high frequency welding, and some products are also subjected to online heat treatment to improve weld toughness.Before leaving the factory, the products will undergo hydraulic test, ultrasonic inspection, size accuracy inspection and other full-process inspection.

We not only have quality products, but also considerate service.The company supports the provision of samples, so that customers can intuitively feel the product quality; also supports professional testing, so that the quality is more guaranteed.In terms of packaging and delivery, scientific and reasonable methods are adopted to ensure that the products are transported without damage and delivered in time.Welcome to your consultation!